|

|

|

|

|

|

|

|

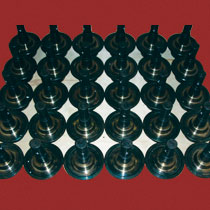

| ROLLERS/IDLERS IN GENERAL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| CARRYING / THROUGHING ROLLERS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RETURN ROLLER WITH SUPPORT RINGS

89/133x2032 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LOWER SUPPORTING ROLLERS

114/133x1176 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| IMPACT ROLLERS 108/159x700 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| FABRICATION OF REVERSIBLE BELT CONVEYOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RETURN ROLLERS WITH SUPPORT RINGS

63/108x1190 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| UPPER SUPPORTING ROLLER 133x1185 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RUBBER COATED UPPER CARRYING

ROLLERS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| RETURN ROLLER RUBBER COATED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| IDLERS FOR FEED PRESS BELT OF PACK. PL. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| CARRYING ROLLERS FOR PACKING PLANT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| RUBBER COATED ROLLERS 133/159x1808 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| IMPACT ROLLERS 108/133x555 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| RETURN ROLLERS 114/133x1426 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| HOLDER ANGLES FOR BUCKET ELEVATORS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| RETURN & UPPER SUPPORTING ROLLERS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| UPPER SUPPORTING ROLLER 159x702 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

COMPLETE RUNNER FOR TABLE OF

PACKING PLANT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RETURN ROLLERS WITH SUPPORT RINGS

89/133x1632 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PAIR OF BUSHINGS - BRONZE FOR SCRW. CONVEYOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CONTROLLED IDLERS READY FOR

SHIPMENT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

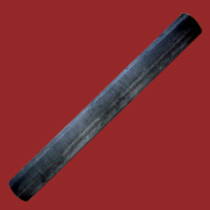

| DRIVE & END SHAFTS FOR SCREW CONVEYORS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

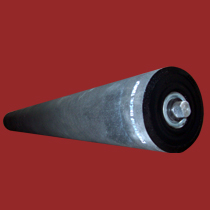

RETURN ROLLER WITH RUBBER COATING

159/169x1000 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| CARRYING, IMPACT & RETURN ROLLERS IN WOODEN BOX |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LOWER SUPPORTING ROLLERS

114/133x1632 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

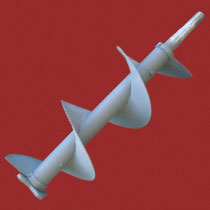

| WORM WING & SHAFT FOR SCREW CONVEYORS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RETURN ROLLERS WITH SUPPORT RINGS

89/133x1600/1640x25 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ROLLERS FOR FEED BELT

108x766 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SUPPORTING ROLLERS

89x650 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| RUBBER COATED RETURN ROLLERS 113/133x1400/1430x20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

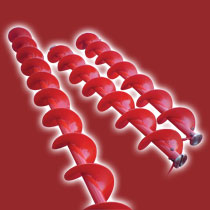

| RH SCREW CONVEYORS FOR MULTI BAG FILTER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| RETURN ROLLERS WITH SUPPORT RINGS 89x133x950 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SNUB PULLEY RUBBER LAGGED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SHACKING LEVER COMPLETED FOR INTENSIVE FILTER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RUBBERIZED RETURN ROLLERS

133/150x950/1000x25 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SUPPORTING ROLLER

159x600 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| CHAIN LINKS FOR DRAG CHAIN CONVEYOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UPPER SUPPORTING ROLLERS

89x1515 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SCREW CONVEYORS LH FOR MULTI

BAG FILTER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RETURN ROLLERS

89x133x1600 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

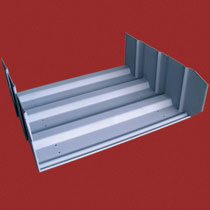

| SCRAPER FOR CHAIN CONVEYOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SUPPORTING ROLLERS FOR WEIGH

FEEDERS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SUPPORTING ROLLS RETAINER FOR

CELLULAR STEEL BELT CONVEYORS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| IDLERS IN SEAWORTHY WOODEN BOXES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| WORM WINGS FOR SCREW CONVEYOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BUCKETS COMPLETE FOR APRON

CONVEYOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| INSPECTION COVERS FOR BELT CONVEYOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| DRIVE PULLEYS WITH SHAFTS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BUCKETS WITH SUPPORTING ROLLERS

FOR PAN CONVEYOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| BUCKET BOTTOM PLATES FOR APRON CONVEYORS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| LOWER STRAND CARRYING IDLERS RUBBERIZED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SUPPORTING ROLLERS FOR STEEL BELT CONVEYOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| RUBBER COATED SNUB PULLEYS FOR BC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| STANDARD COVERS FOR BELT CONVEYOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| BUCKETS FOR APRON CONVEYOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| BUCKETS WITHOUT SUPPORTING ROLLERS FOR PAN CONVEYOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| RETURN ROLLERS WITH DISCS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PRESSURE PULLEYS WITH DIAMOND PROFILED RUBBER COATING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DEVIATION PULLEY WITH RUBBER

LAGGING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| UPPER SUPPORTING IDLERS FOR BC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PANS WITH SUPPORTING ROLLERS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PANS WITHOUT SUPPORTING ROLLERS |

|

|

|

|

|

|

|

| MATERIAL HANDLING : |

| Covering all conveying system spares/attachments, worm wings, hanger bearings, drive & end shafts for screw conveyors, conveyor belts, endless belts, sprockets, roller & plate type of chains, chain links, buckets, pans for pan conveyors, holder angles, central bearings, couplings & etc. facrication of reversible belt conveyors, complete screw conveyors also for belt conveyors idlers/rollers/pulleys & relevant spares; |

| » |

throughing-carrying idlers, |

| » |

impact idlers with rubber rings, |

| » |

return rollers with rubber discs, |

| » |

drive pulleys, snub pulleys, extension pulleys / tension drums, head pulleys with rubber lagged as of

diamond or herringbone groove pattern, |

| » |

screens / bearing housings, |

| » |

idler group station frames / brackets. |

|

|

| As specifically for idlers/rollers/pulleys; |

| * |

pipes (roller body- shell material) are of longitutional welded steel specific idler pipes. |

| * |

shaft materials are of SAE 1040 / SAE 1050 / St-52 in general with tolerances of h9. |

| * |

bearings are of ; SKF/FAG. |

| * |

sealings are of; polyamid 6 quality and grease lubricated which has resistance up to 180-200° C. |

| * |

idler bodies; applied as electro-static furnace painted with epoxy-polyester, colour RAL 3000-red

with 60-90 micron thickness. |

| * |

bearing housings are of; as resistant to heavy working conditions and bearing housings welded to

pipe (idler body) as double sided with peripheral automation system. |

| * |

in case of rubber lagging or having rubber discs (rings) are of 60+/-5 deg. SHORE A hardness value. |

| * |

shipping all idlers / rollers / pulleys as of clean with no defects and also as assembled and ready for

installation. |

|

|

|

TEKNOBIR INDUSTRIAL CONSULTING ENG.LTD. © Copyright. Files you see here are hosted on the server.

It is strictly prohibited to upload any

copyrighted material without explicit permission from copyright holders. |

|

|

|