|

|

|

|

|

|

|

|

| VARIOUS FIXING ELEMENTS IN GENERAL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SUSPENSION BOLT FOR INTENSIVE

FILTER, L=520 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| CYLINDIRICAL BOLT Ø 125 X 238 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ECCENTRIC BOLT WITH MOUNTING PLATE FOR GRATE COOLER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| M24 HEX. HEAD BOLT WITH WASHER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

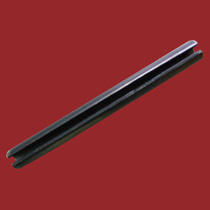

SPRING PIN FOR CLINKER CRUSHER

HAMMER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M24 X 85 COUNTERSUNK NIB

BOLT WITH NUT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| T-BOLT COMPLETE FOR COOLER PLATES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| BOLT WITH SPRING WASHER & NUT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| FILLISTER HEAD COUNTERSUNK SCREW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LINER BOLT WITH NUT

M36x3x20x80x200 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HEX BOLT WITH NUT

M24x3x65x90 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| HEX. LOCKING NUT M24x2 DIN 980 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAP SCREW DIN 912 M36x70 MM

FOR RAW MILL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

COUNTERSUNK NIB BOLT WITH LOCKING

NUT FOR CRUSHER LINER PLATES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SPECIAL TYPE OF SETTING BOLTS

WITH NUT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| M42 BOLT WITH NUT FOR PROTECTIVE SEGMENTS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SEGMENT REMMER BOLT WITH NUT FOR CELLULAR STEEL BELT CONVEYOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SUSPENSION BOLT FOR INTENSIVE

FILTER, L=460 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| COUNTERSUNK SCREWS WITH NUT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LINER BOLT WITH NUT

M36x3x20x80x220 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SQUARE HEAD BOLTS WITH NUT FOR CM |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DIN 933 HEX. HEAD BOLT

M24x2x100 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PIVOT BOLT FOR BAG FILTER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ALL COMPONENTS FOR BELT BUCKET ELEVATORS BOLTS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| M30x350 SQUARE HEAD BOLT NUT & WASHER FOR CEMENT MILL LINERS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SQUARE HEAD BOLT & WASHER FOR

KILN OUTLET |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| STAINLESS STEEL T-HEAD BOLT WITH SQUARE NECK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| NOSE RING SETTING BOLTS FOR ROTARY KILN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SQUARE HEADED BOLTS FOR CLINKER CRUSHER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| T-HEAD BOLTS FOR CEMENT MILL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| NOSE RING SETTING BOLTS AS SETS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| CUP WASHERS FOR ROTARY KILN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| STUDS, M56x1120 FOR RAW MILL |

|

|

|

|

|

|

|

SPECIAL & STANDARD TYPE OF FIXING ELEMENTS :

Numerous special and standard type of fixing elements such as; forged T-bolts, hexagonal, cyclindirical, eccentric, countersunk, break-off, square head, hammer head, socket head & etc. bolts together with nuts, flat & spring washers, locking nuts, pins, screws, anchorage bolts as of material qualities corresponding to SAE / DIN / BS / JIS / GOST norms with exact grades as per specifications, heating and shaping operation by using drop forging machineries or friction presses one by one and cooling in tempering furnaces which are having heat control with the aim of dropping the temperature as slow as the necessary rate under full control of proper cooling of the formed material as considering an important phase the cooling rate effects the various porperties, then machining bolts and nuts in automatic turning lathes with great care as the bolts are being formed by thread rolling system, briefly this system is forming the bolts by using two turning rolls which are under hydraulic pressure and passing the bolts through them. Using this method enables us to have material which does not contain any discontinuties in micro-structure. (On the contrary, if bolts; machined by chipping as done in primitive methods then in micro-structure of material there may be discontinuties in metal fibers which causes to decrease the physical properties)

After machining bolts & threads final heat-treatment process to take of the possible humidity and also heating up to temperature which is convenient for the characteristic of the material used then quenching & tempering, at the final stage; final precise quality control as regards to all dimensions and physical properties prior to packaging for shipment.

|

|

|

TEKNOBIR INDUSTRIAL CONSULTING ENG.LTD. © Copyright. Files you see here are hosted on the server.

It is strictly prohibited to upload any

copyrighted material without explicit permission from copyright holders. |

|

|

|