|

|

|

|

|

|

|

|

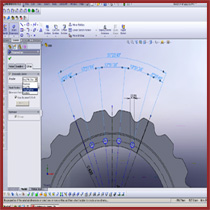

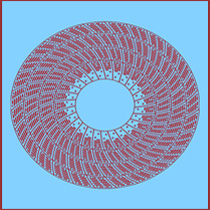

| PREPARATION OF FINAL MANUFACTURING DRAWINGS FOR SPROCKET SEGMENTS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

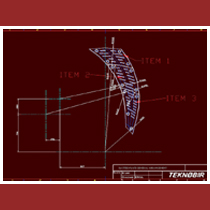

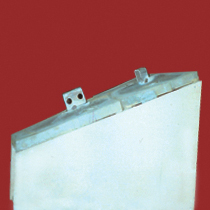

PREPARATION OF GEN. ARRANGEMENT

LINE DRAWINGS OF DIAPHRAGM PLATES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

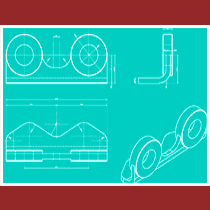

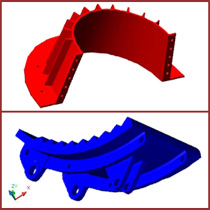

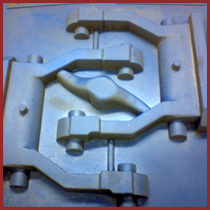

| PREPARATION SKETCHES OF HOLDER ANGLES FOR BUCKET ELEVATORS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

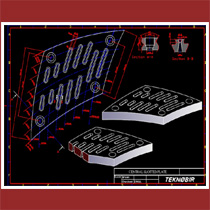

| PREPARING FINAL MANUFACTURING DRAWINGS FOR DIAPHRAGM PLATES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

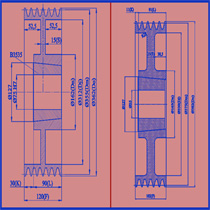

| PREPARING V-BELT PULLEY SKETCHES BEFORE MANUFACTURING PROCESS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PREPARATION FINAL DRW'S BEFORE INITIATING THE PRECISE MANF'G PROCESS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

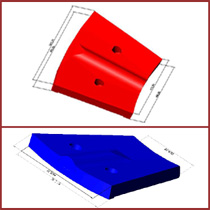

| SOLID MODELLING FOR EACH INDIVIDUAL LINER PRIOR TO ASSEMBLY CONTROL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

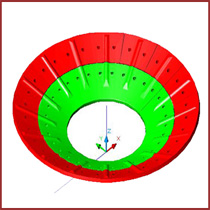

| PREPARING GEN. ASSEMBLY SOLID MODELLING PRIOR TO MASS PRODUCTION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PREPARATION OF SOLID MODELLING FOR PATTERNS CONTROL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PREPARING GEN. ASSEMBLY DRW. FOR

EACH LINE OF DIAPHRAGM PLATES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PREPARING GENERAL ASSEMBLY

DRAWINGS FOR DIAPHRAGM PLATES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PREPARATION OF DIMENSIONAL CONTROL REPORTS FOR RINGS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

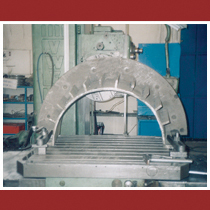

| CONTROLLING THE PATTERNS COMPLETELY PRIOR TO CASTING PROCESS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PREPARING PATTERN CONTROL PLATFORMS FOR CHECKING PRE-INSTALLATION LINERS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CHECKING PATTERN FOR SHRINKAGE

PRIOR TO MOULDING PROCESS PRECISELY |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| CHECKING THE RAW CASTINGS BEFORE MACHINING PROCESS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PREPARING STEEL TEMPLATES FOR ACCURATE CONFIGURATIONAL CONTROL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| INSPECTION & SUPERVISING DURING MACHINING PROCESS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

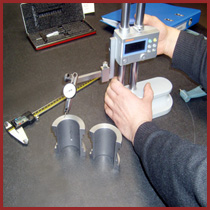

| SENSITIVE DIMENSIONAL CHECK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| EXACT DIMENSIONAL CONTROL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ASSEMBLY CONTROL OF RING SEGMENTS PRIOR TO PACKAGING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PENETRANT TEST FOR CRUSHER HAMMERS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PENETRANT TEST FOR ALL CRUSHER HAMMERS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ULTRASONIC INSPECTIONS FOR WELDING JOINTS OF FABRICATED PARTS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| COMPLETE ASSEMBLY CONTROL OF DIAPHRAGM PLATES BEFORE PACKAGING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| EXECUTING PART BASIS INSPECTIONS PRIOR TO SHIPMENT PROCEDURES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| NUMBERING SEGMENTS DURING ASSEMBLY CONT. FOR EASY INSTALLATION AT PLANT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BUNDELING SPROCKET SEGMENTS

FOR EACH SET SEPERATELY |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

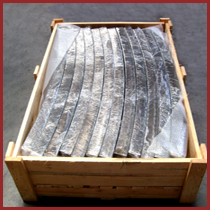

PROTECTION EACH FINISHED PRODUCT

BY APPLYING ANTI-RUST LUBRICANT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SEPERATELY EXACT PROTECTION FOR

EACH PART DURING SHIPMENT PACKAGING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| APPLYING SEAWORTHY PACKING PRECISELY |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| APPLYING SEAWORTHY PACKING BY PROTECTED WOODEN BOXES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| COMPLETELY STRAPPED & PROTECTED WOODEN PALLETS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| LOADING WOODEN BOXES ON TRUCKS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| TRUCKS IN CUSTOM AREA AT EXPORT TERMINAL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| LOADING IN TO CONTAINERS AT EXPORT TERMINAL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LOADING PREPARATIONS ON TO

FLAT-RACK CONTAINER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| EXECUTING SAFE LASHING PROCESSES AT SEAPORT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| LOADING COMPLETED ON TO FLAT-RACK CONTAINER |

|

|

|

|

|

|

|

FUNDAMENTAL PARAMETERS :

| » |

Implementation of engineering solutions for the most convenient material selection pertaining to

mechanical properties with existing working conditions and type of wear for the parts/components

in place of use at plant, |

|

|

| » |

Specialized studies on preparation & upgrading relevant lay-outs, final manufacturing & solid model drawings on each part / attachment / component basis seperately alongwith general arrangements – assembly drawings for accurate configurational, operational & dimensionalwise products, |

|

|

| » |

Realization of strict raw & subsidiary materials controls as analyzing/testing qualitative data fully corresponding to determined/required chemical analysis & mechanical properties and also keeping material acceptance records, |

|

|

| » |

Setting-up methodical studies covering whole manufacturing/fabrication and/or hardfacing processes through integrated material supply management system,

|

|

|

| » |

Carrying out continuous extensive equipment manufacturing phases inspections comprising of;

patterns, results of liquid metal-spectral analysis, mouldings, prototypes - samples, templates,

allowances, mass production, sand blasting, all rough & sensitive grinding, proper heat treatment

(normalizing, annealing, hardening, stress relieving, quenching, tempering & other special heat

treatments for castings and case hardening, carburizing-cementation, induction surface hardening

processes for various mechanical spares) finish machining, static & dynamic balancing, welding,

hardfacing/coating processes on parts in accordance with specific operational characteristic of the

each part/component itself, |

|

|

| » |

Executing perpetual rigid quality planning & control processes in terms of NDT & DT as based on

designated chemical composition & mechanical properties as well as conforming for the complience

of dimensions according to final manufacturing drawings and preparing quality control forms related

to each part/component solely furthermore also marking all parts aiming at complete traceability for

assurance of reliability of the products and supplying tailored-made products of which are fully

matching with plant’s technical needs always. |

|

|

| » |

Supervision of assembly processes prior to initiating appropriate seaworthy packing & shipment

procedures, completely for alignement, installation & fixation of the parts as ready to use at plant. |

|

|

|

|

TEKNOBIR INDUSTRIAL CONSULTING ENG.LTD. © Copyright. Files you see here are hosted on the server.

It is strictly prohibited to upload any

copyrighted material without explicit permission from copyright holders. |

|

|

|